Optimized Seating Comfort Through Simulation

Seating comfort as a differentiating factor

Whether in a classic or an autonomous vehicle, the seat should first and foremost support us in adopting a safe and ergonomic posture in all situations and for all activities. Nowadays, that is a prerequisite. Comfort, on the other hand, is an important feature by which the manufacturer can differentiate itself from the competition.

Making seating comfort objectively assessable

One of the decisive evaluation variables for dynamic seating comfort is the seat transfer function. It indicates how good the insulating properties of a seat are and reflects the behavior of the complete system consisting of the person, upholstery and seat structure. The seat pressure distribution in particular is used to evaluate static seating comfort. In addition, there are other measured variables and methods for evaluation. Simulation makes it possible to reproducibly determine and optimize the decisive factors in the early stages of seat development.

Our service portfolio in the field of seating comfort:

- Seat modeling

- Static and dynamic comfort simulations

- Parameter studies of seat designs

- H-point and backset simulation

- Comfort benchmarks/comfort analysis

- Experimental modal analysis of seats and structures

- Development and construction of individual comfort test systems

We support you either by taking over individual tasks or by covering the complete process chain – if desired also supplemented by measurements to validate the virtual results. Particularly complex and highly demanding simulation tasks are our specialty.

We also supply the right tools for seating comfort analysis

Our physical vibration dummy MEMOSIK® and our virtual occupant model CASIMIR play a special role in our service portfolio in the field of seating comfort. While CASIMIR is at home in the purely virtual world of seat development, MEMOSIK is also available for test drives. Both have in common that they replace the occupant for comfort evaluations and thus make an important contribution to objectification.

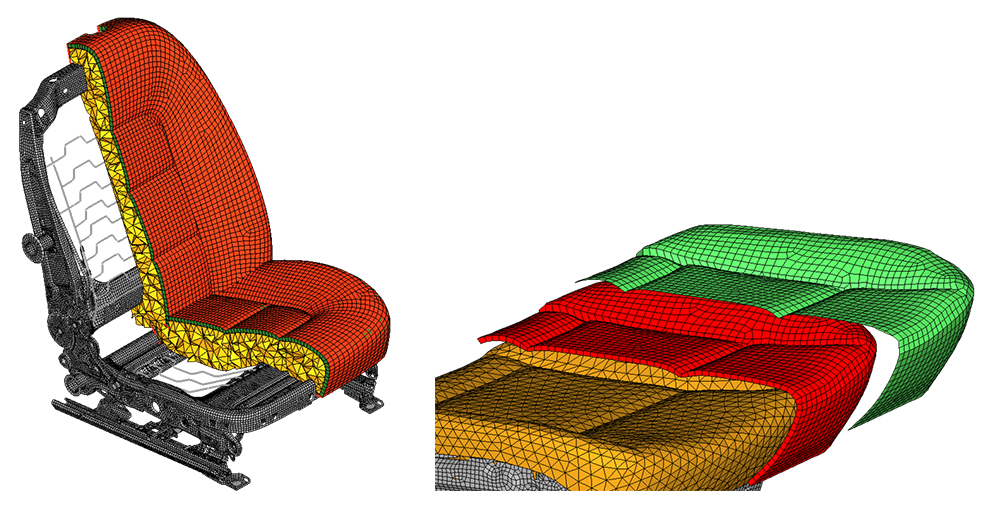

Exact Seat Modeling as the Basis for Comfort Simulation

The starting point of every comfort simulation is the construction of a finite element model of the seat. This consists of:

- The seat structure including kinematics, adjusters and joints

- Lower and rear suspension

- Molded foam components (with laminations, if necessary)

- Seat cover

Decisive for the suitability of the seat model for vibration simulations are the exact reproduction of the natural frequencies and shapes as well as the reproduction of the special material properties of the molded foam parts and cover (especially their frequency dependence).

We take on the precise modeling as well as the material tests, which are necessary for the simulation of the foam and cover materials.

We also supply the right tools for seating comfort analysis

Our physical vibration dummy MEMOSIK® and our virtual occupant model CASIMIR play a special role in our service portfolio in the field of seating comfort. While CASIMIR is at home in the purely virtual world of seat development, MEMOSIK is also available for test drives. Both have in common that they replace the occupant for comfort evaluations and thus make an important contribution to objectification.

Ideal Occupant Position Through Virtual H-Point Simulation

In the seat design, the so-called Seating Reference Point (SgRP) is defined at the beginning. This is a reference value for the occupant's position in the vehicle and thus a fixed point for the entire interior design. A seat is developed in such a way that the occupant, starting from this point, reaches all relevant components and sits safely and comfortably. There is a tolerance field around the SgRP in which the measured H-point (hip point) must lie.

Early approximation of the H-point to the SgRP

Our simulation methodology shows how large the deviation between the two points is. For this purpose, the seat model from the static comfort simulation is merged with a model of the H‑point manikin according to SAE J826. With deviations of only a few millimeters, the predictions obtained are very close to the measured values of prototypes built later. This means that measures for approximating the H-point to the SgRP can already be developed and implemented in the virtual development phase.

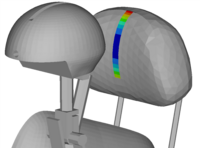

Backset simulation for determining the head restraint distance

In conjunction with the Head Restraint Measuring Device (HRMD) according to FMVSS TP 202a, we additionally determine the head restraint distance (backset) in analogy to the test according to regulations.

We also supply the right tools for seating comfort analysis

Our physical vibration dummy MEMOSIK® and our virtual occupant model CASIMIR play a special role in our service portfolio in the field of seating comfort. While CASIMIR is at home in the purely virtual world of seat development, MEMOSIK is also available for test drives. Both have in common that they replace the occupant for comfort evaluations and thus make an important contribution to objectification.

Seating Comfort Benchmarked Against a Comparative Product

Benchmark studies are always interesting when you want to find out which comfort characteristics a vehicle or a seat has compared to other vehicle classes or comparable products and how the differences are quantified.

Within the scope of your benchmark project, we record and evaluate among other things:

- the static and dynamic pressure distributions on the seat and backrest,

- the seat transfer functions (measured with MEMOSIK® for the percentiles f05, m50, m95),

- the vibration effects on the occupant and

- the dynamic properties of structures and complete seats using Experimental Modal Analysis.

The tests can take place both on a test bench and directly in the vehicle.

Product improvement by comparison with a benchmark product

If you want to use the benchmark project specifically for product improvement, we will be glad to advise you on how to combine the positive properties of your product with those of the comparison product.

We also supply the right tools for seating comfort analysis

Our physical vibration dummy MEMOSIK® and our virtual occupant model CASIMIR play a special role in our service portfolio in the field of seating comfort. While CASIMIR is at home in the purely virtual world of seat development, MEMOSIK is also available for test drives. Both have in common that they replace the occupant for comfort evaluations and thus make an important contribution to objectification.

Experimental Modal Analysis (EMA) for Solving Vibration Problems or for Model Updating

The Experimental Modal Analysis (EMA) can be used to determine the relevant vibration characteristics of vehicle seats by measurement, for example as part of NVH investigations:

- Natural frequencies

- Natural modes of vibration

- Modal damping ratios

The results can either be used directly for the analysis and solution of a vibration problem or, in the context of model updating, for the verification or optimization of an existing finite element model.

Due to the non-linear properties of seats, special procedural know-how is required here. We offer modal analysis of seat structures (i.e. without upholstery) as well as of fully upholstered seats.

We also supply the right tools for seating comfort analysis

Our physical vibration dummy MEMOSIK® and our virtual occupant model CASIMIR play a special role in our service portfolio in the field of seating comfort. While CASIMIR is at home in the purely virtual world of seat development, MEMOSIK is also available for test drives. Both have in common that they replace the occupant for comfort evaluations and thus make an important contribution to objectification.

Please contact us personally

________

We will gladly advise you on questions related to (virtual) seat development, seating comfort and virtual human models.

M. Sc.

Aravinda Veeraraghavan

Technical Support

+49 931 49708-182

veeraraghavan@woelfel.de

Contact form

Computational Mechanics of Materials and Structures, Universität Stuttgart

M.Sc.

Learn and use latest technology to benefit the customers.

To be at the top of innovation.

Computational Mechanics of Materials and Structures, Universität Stuttgart

M.Sc.

Learn and use latest technology to benefit the customers.

To be at the top of innovation.

![[Translate to English:] Sitzkomfort [Translate to English:] Sitzkomfort](/fileadmin/_processed_/6/4/csm_2021-02-automotive-sitzkomfort_800_700_f679491445.png)

![[Translate to English:] Software & Systeme Sitzkomfort [Translate to English:] Software & Systeme Sitzkomfort](/fileadmin/_processed_/b/8/csm_2021-02-automotive-sitzkomfort_2_800_700_7ef4dee711.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/f/csm_2019-11-kachel-dummys_02_d5f2003f99.jpg)