Component Optimization – The Path to the Best Possible Product in the Shortest Possible Time

Product innovations should be light, safe, comfortable, efficient and durable. At the same time, lead times are becoming shorter and shorter. Not only are the demands on the product itself increasing, but also on the development process.

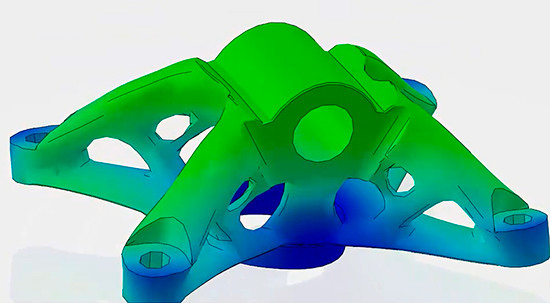

The early use of optimization techniques makes the product more efficient on the one hand, while at the same time reducing the number of complex prototype tests and significantly shortening the development time on the other. In principle, a distinction is made between parameter and topology optimization.

The basis for successful optimization is the definition and prioritization of goals that are as precise as possible, for example with regard to weight, material costs and safety. Using powerful FE solvers, various design variants can then be virtually created, tested, compared and further developed until the product meets the requirements defined at the outset.

The advantages of optimization techniques at a glance:

- Improved overall product performance

- Shorter development time

- Early recognition of problem areas

- Cost savings due to low number of physical prototypes

- Longer-lasting and lighter components and products

- Discovering new design possibilities

PLEASE CONTACT ME PERSONALLY

________

I am happy to support you with numerical simulations and advise you on the development, optimization and automation of your simulation processes.

Mechanical Engineering, TU Darmstadt

Dr.-Ing.

Mastering the variety of technical challenges together with our customers and with the Wölfel team through innovative solutions.

![[Translate to English:] Sitzkomfort [Translate to English:] Sitzkomfort](/fileadmin/_processed_/6/4/csm_2021-02-automotive-sitzkomfort_800_700_f679491445.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/f/csm_2019-11-kachel-dummys_02_d5f2003f99.jpg)