Whether German, European or international regulations (DIN EN 1998, IBC, UBC, KTA, IEEE, IEC, etc.) – Our know-how covers earthquake standards worldwide

In order to be able to offer high quality earthquake engineering for our customers with projects all over the world, we intensively and continuously deal with earthquake standards worldwide. To name a few project examples:

- Control cabinet in Chile (NCh2369)

- Brewery boiler in California (ASCE 7)

- Packaging facility in Australia (AS 1170)

- Nuclear interim storage facility in Germany (KTA 2201)

- Data center in Turkey (DBYBHY 2007)

- Substation in the USA (IEEE 693)

- Switch cabinet in China (IEEE 344)

However, we do not only apply them in numerous projects. In our seminars, we regularly communicate all new developments worth knowing about the most important regulations and contribute our specialized knowledge to standards and regulations committees.

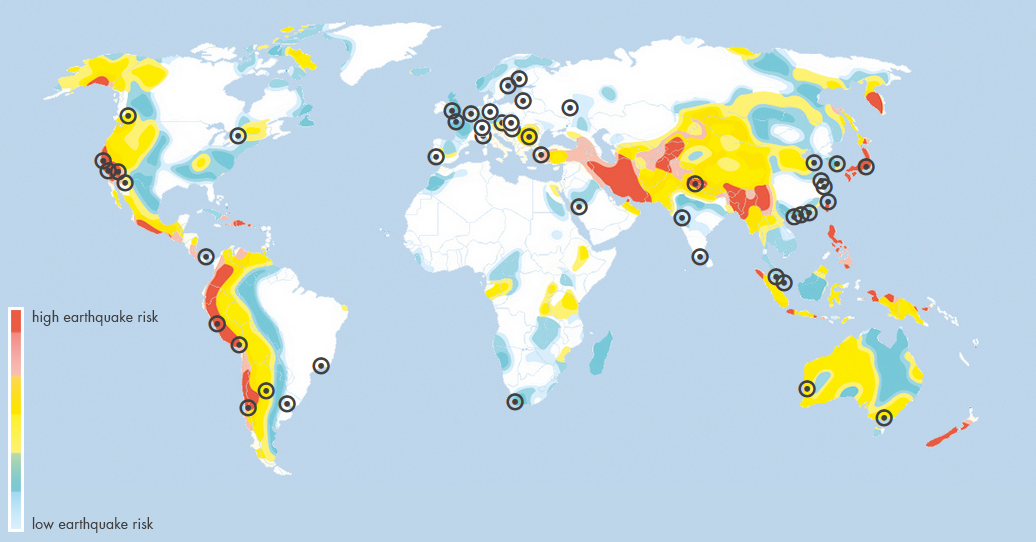

Equipped for earthquake load cases worldwide

All requirements met: On the safe and economical side with customized services and systems

Our solutions for conventional as well as nuclear plant construction, which is characterized by higher requirements, are just as individual as your projects. Depending on your demands, we offer a complete package or support you with individual services:

- Development and implementation of a verification concept for...

... Plant structures (e.g. power plants, chemical plants, production plants, switchgears)

... Plant parts, components and their anchorages - Verification calculation with (quasi-)static equivalent methods, spectra methods (RSMA), linear or non-linear time history calculations or probabilistic methods

- Planning, specification, implementation and evaluation of earthquake tests by vibration testing

- Similarity considerations by using existing earthquake proofs

- Determination of the soil-structure interaction by means of special simulation programs, e.g. for the determination of response spectra

- Assessment of earthquake damage, incl. classification of damage patterns

- Seismic re-evaluation of existing buildings, plants, machines or components by inspection, calculation or measurement

- Elaboration of proposals for the retrofitting and upgrading of existing buildings, machinery and equipment

- Preparation of auditable and quality-assured documentation of all work and results in accordance with national and international requirements

- Preliminary review and quality assurance of third-party design documents for the operator

- Support in technical discussions with contractors, assessors and authorities

- Representation vis-à-vis inspectors and authorities

- Earthquakes in plant engineering

- Earthquakes and other special loads

References

In an LNG terminal, which was built in a region with high seismic risk, continuous earthquake monitoring of the storage vessels and plant components had to be ensured. Furthermore, it had to be ensured that in case of an earthquake, appropriate messages are displayed in the control room and measures for personal and plant protection are automatically initiated.

Please contact me personally

________

I will be happy to advise you on questions relating to your earthquake engineering project.

Mechanical Engineering, TU Darmstadt

Dipl.-Ing. / Dr.-Ing

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_2021-12-foerderband-saftflaschen-iStock-1253733832-gekauftk_5764ae728a.jpg)