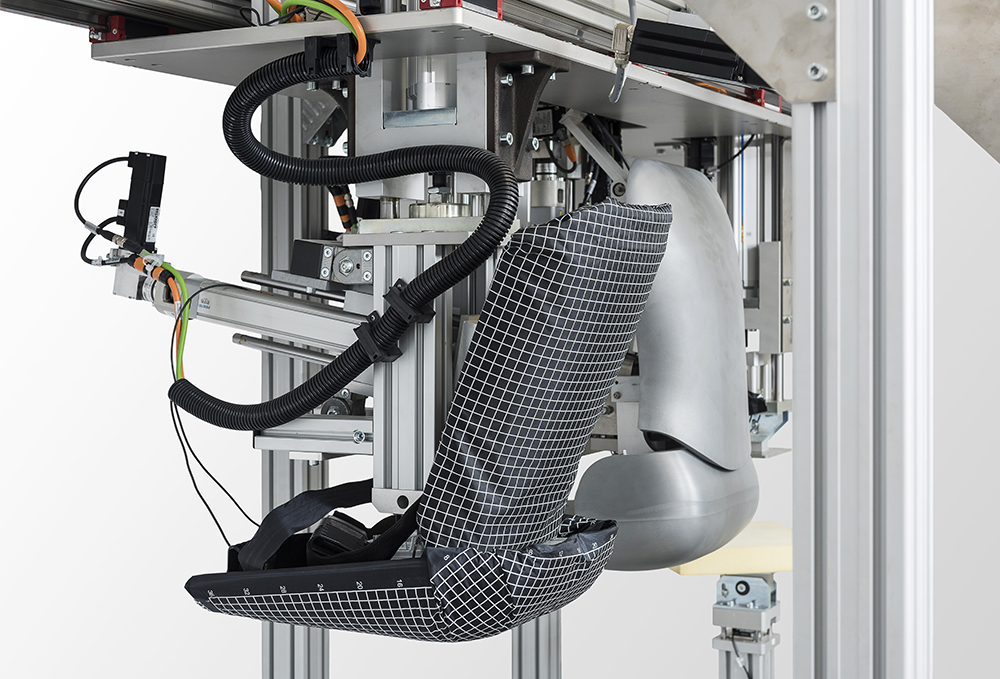

Seat Test Benches for the Objective Evaluation of Seating Comfort

In order to meet the high demands placed on modern seats, the reliable and reproducible determination of the relevant evaluation variables during development and production is crucial. Although test persons reflect the actual application scenario, they also contain a great deal of uncertainty due to their subjectivity and low reproducibility.

These uncertainties can lead to incorrect decisions, and corrections are often extremely time-consuming and costly. Automated seat test benches, on the other hand, provide unambiguous, reproducible and comparable results.

Learn more in the following video.

They are primarily used in two areas:

![[Translate to English:] In der Entwicklung [Translate to English:] In der Entwicklung](/fileadmin/user_upload/innovation-02.png)

In development

A typical field of application is the determination of seat pressure distribution and seating behavior as well as the hysteresis of the entire seat within the scope of variant evaluations or benchmarks. Based on the objective and reproducible results, different variants can be compared much more reliably.

Another area of application is the automated H-point and backset measurement in accordance with the SAE J826 and FMVSS 202a standards.

![[Translate to English:] In der Fertigung [Translate to English:] In der Fertigung](/fileadmin/zentrale-elemente/icons/mechanical-arm.png)

In production

Typically, seating comfort, the function/calibration of the seat-belt reminder or seat occupancy detection, adjuster noise or handling forces are monitored. All quality-, comfort- and safety-relevant parameters can be reliably and precisely tested.

Documentation of the results enables consistent quality assurance. If necessary, it is possible to intervene in the production parameters at an early stage.

Customized Development – Complete Solution from a Single Source

Several OEMs have been relying on our individual test systems for vehicle seats for many years. For design, development and construction, we can draw on our many years of experience in the fields of seating comfort and simulation of passenger car seats.

You receive a comprehensive solution consisting of:

- Measuring and testing technology/sensor technology

- Software and sequence control

- Automation technology

The test results can be visualized with a variety of evaluation methods.

References

Please contact us personally

________

We will gladly advise you on questions related to (virtual) seat development, seating comfort and virtual human models.

M. Sc.

Aravinda Veeraraghavan

Technical Support

+49 931 49708-182

veeraraghavan@woelfel.de

Contact form

Computational Mechanics of Materials and Structures, Universität Stuttgart

M.Sc.

Learn and use latest technology to benefit the customers.

To be at the top of innovation.

Computational Mechanics of Materials and Structures, Universität Stuttgart

M.Sc.

Learn and use latest technology to benefit the customers.

To be at the top of innovation.

![[Translate to English:] Sitzkomfort [Translate to English:] Sitzkomfort](/fileadmin/_processed_/6/4/csm_2021-02-automotive-sitzkomfort_800_700_f679491445.png)

![[Translate to English:] Dienstleistung Sitzkomfort [Translate to English:] Dienstleistung Sitzkomfort](/fileadmin/_processed_/b/8/csm_2021-02-automotive-sitzkomfort_2_800_700_7ef4dee711.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/f/csm_2019-11-kachel-dummys_02_d5f2003f99.jpg)