Active Vibration Reduction Enables Leaps in Productivity

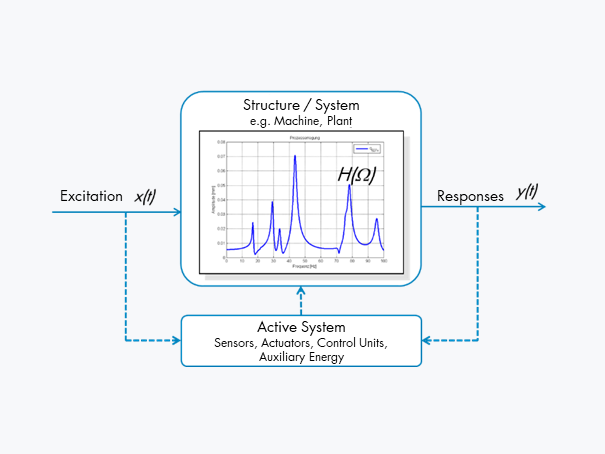

Active solutions, in which actuators are used to apply vibration-reducing forces into systems or machines in a targeted manner, are the future in structural dynamics. Innovative technologies open up completely new potentials – for example, machines can be lifted to completely new levels of productivity.

A reduction in vibration is usually accompanied – intentionally or unintentionally – by a reduced noise level, which means that the step to active noise reduction, e.g. as a result of (multi)-tonal vibrations, is not far away.

Development of individual solutions for active vibration reduction

The development of vibration-reducing (AVR) or noise-reducing (ANC) active solutions, usually individually tailored to a task, requires comprehensive competence in

- Structural dynamics and vibrations,

- Measurement technology,

- Control and software engineering,

- Hardware development (actuator, amplifier, sensors) as well as

- Product qualification for operating conditions

and demands a high degree of constructive creativity.

With our team of young, innovative engineers, backed up by decades of experience in the field of dynamics in our company, we are ideally equipped to solve these tasks for you.

Our specialties

_____________

While some tasks – for example, making production more efficient or reliable and complying with occupational health and safety regulations – are similar for all machine types, there are also individual challenges in each industry. Over the past decades, in countless projects for manufacturers and operators of paper machines and machine tools, we have been able to build up valuable specialist knowledge in these industries:

References

Find out in this case study how a milling machine achieves better results with the help of a retrofitted Active Vibration Reduction system. Simply fill out the form on the right and the PDF will reach you by e-mail (sender: Wölfel Group).

Find out in this case study how a cutting machine achieves much better results by integrating an Active Vibration Reduction system on the spindle. Simply fill out the form on the right and the PDF will reach you by e-mail (sender: Wölfel Group).

Please contact us personally

________

We will be happy to advise you on questions relating to vibrations and noise in mechanical engineering.

Dr.-Ing.

Marcus Ries

Head of Vibration Measurement + Reduction

+49 931 49708-370

ries@woelfel.de

Contact form

Mechanical Engineering, TU Darmstadt

Dipl.-Ing. / Dr.-Ing

![[Translate to English:] Gehörschutz [Translate to English:] Gehörschutz](/fileadmin/_processed_/b/5/csm_Maschinenbau_Elektrotechnik_08_Maschinenakustik_1000_875_89af5fdda6.jpg)